Selecting the Right Combination Sewer Cleaner

by Vactor Team, on Dec 10, 2021 1:14:00 PM

When selecting a combination sewer cleaner to clean sewer lines and remove blockages, it’s important to consider the application for which the machine will be used the most.

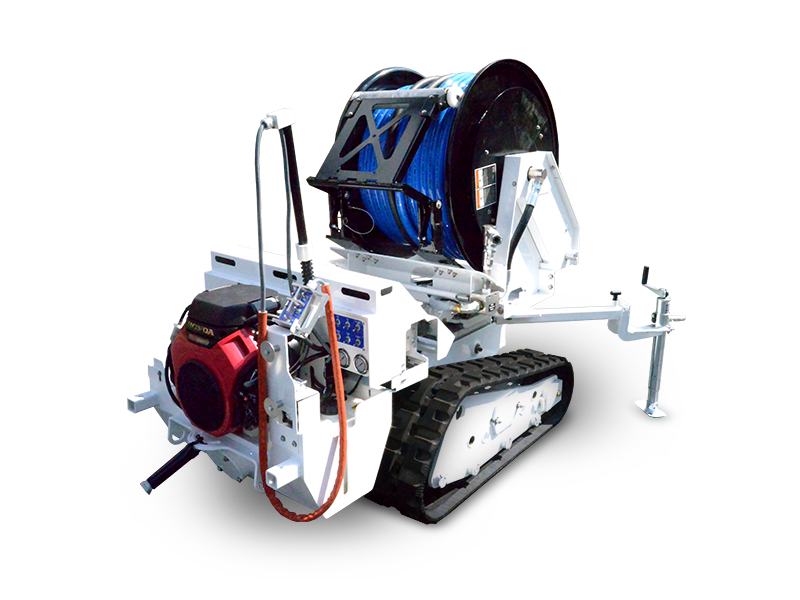

A combination sewer cleaner uses high-pressure water and vacuum to clear and clean sewer lines. The unit is self-contained with its own water supply tanks, debris body, vacuum system, rodder pump, hose reel, high-pressure water hose and hydraulic pump. All combination sewer cleaners rely on air conveyance to move the material from the sewer line to the debris body.

Customers have two styles of trucks to choose from to convey material: a centrifugal fan compressor, or a positive-displacement unit.

How fan units work

Fan units use rotating fan blades to compress air in compound stages. The air is drawn to the inlet of the fan blade, and as the blade spins, it moves and compresses the air. Fan units are capable of lifting a column of water 200 inches – approximately 14 inches Hg. These units can vacuum material under water up to their rated lift performance, with or without air induction. The closest tolerance in a fan is about 1/4 of an inch.

The key for the most efficient operation is to gain the most compression and create as much tip speed as possible to move the most air. The larger the diameter of the fan, the more air it moves.

With fan units, if the debris bodies fill to capacity and overflow, the debris is ejected into the atmosphere. Fan units use air movement to lift material and debris up the hose and into the hopper.

Best applications

Fan units are the right choice for all-around sanitary and storm sewer cleaning. While fan units tend to handle drier materials well, they can move liquids and solids at more than 100 feet vertically or horizontally. Fan units also work best with light and loose materials, dry to wet, short to moderate pulls, with low to moderate flowing lines.

How PD units work

PD combination sewer cleaners feature two lobes that rotate in opposite directions of each other. Each lobe traps a certain amount of air per rotation. PD machines rely on close tolerances to trap the air. Relief valves help protect the units from building too much vacuum, which can create too much heat, causing internal components to expand and collide with each other.

PD units take air from the inlet side, compress the air, and move it from one side to the other at a high rate. While PD units move air, they also create a vacuum if the airflow is blocked. These units will continue to take air from within the debris bodies, pickup tubes, and filters, creating negative air pressure within the system.

Once PD units reach lift capacity, operators must add air to continue conveying material to the holding vessels. PD units will continue to move water and material even if the pickup tubes are buried.